Release time:2024-10-23

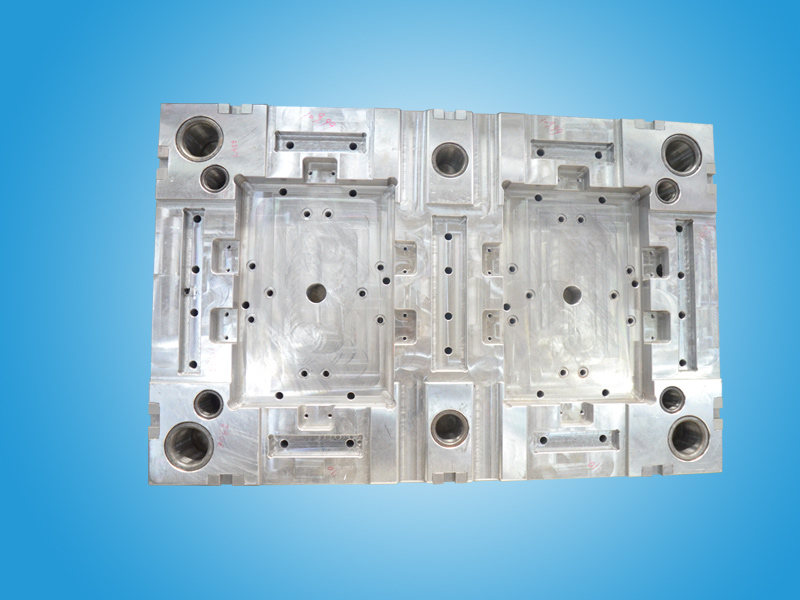

Many at presentElectronic product shellThe material of aluminum alloy is mainly aluminum alloy, and aluminum alloy products have become one of the mainstream products in the electronic industry. All kinds of shells made of aluminum alloy are widely used in the electronic industry because of their convenient processing, high flexibility and high grade, which can effectively increase the added value of products. They usually include aluminum profile shell and aluminum die-casting shell. So what are the characteristics of aluminum alloy shell processing?

1. Good conductivity and thermal conductivity: the conductivity and thermal conductivity of aluminum are second only to silver, copper and gold.

2. Low density: the density of aluminum and aluminum alloy is close to 2.7g/, about 1/3 of that of iron or copper.

3. Easy to handle: after adding some alloy elements, forged aluminum alloy with outstanding forging function or deformed aluminum alloy with good processing plasticity can be obtained.

4. High strength: aluminum and aluminum alloys have high strength. After a certain degree of cold working, the strength of the matrix can be strengthened, and some aluminum alloys can also be strengthened by heat treatment.

Aluminum shell is widely used in the electronic industry because of its convenient processing, high flexibility and high grade, which can effectively increase the added value of products.

In daily life, daily necessities made of aluminum profiles account for a large proportion, such as mobile power enclosures, aluminum doors and windows, which require a lot of maintenance to make things made of aluminum profiles more durable.

With the rapid development of electronic products, the shell, as the protective packaging of electronic products, has a wide range of materials. The most popular is the aluminum profile shell. Based on the conventional titanium plating process, the pre plating and electroplating technical steps are added. In the production of aluminum profiles, the activated galvanized parts are put into the aqueous solution of salt and hydrochloric acid for chemical treatment. It can be processed into a variety of series of bright aluminum products in gold, color, black and other forms. Precautions for aluminum profile shell during stretching:

1. The stretching of aluminum alloy profile must be cooled to below 50 degrees before it can be moved to the stretching frame for stretching operation. If the temperature is too high, stretching will not only burn the human body, but also burn if it is burned. Moreover, because the internal stress of aluminum alloy profile cannot be completely removed, it will show twists and turns, twisting, poor function and other absolute waste products before and after aging.

2. The stretching amount should be controlled at about 1%. It should be noted that if the stretching amount is too large, there will be scale errors in the head, middle and tail, watery distortion (fish scale) marks in the appearance, low elongation, high hardness, and high brittleness (low plasticity). Too low stretching amount will make the compressive strength and hardness of the profile low, and the hardness cannot be improved until aging (quenching), and the profile is prone to bending and bending (commonly known as big knife bending).

3. In order to control the tensile deformation and the proportion change of the whole profile, it is necessary to select a suitable special clamping pad and a suitable method. Especially for open materials, circular arc materials, cantilever materials and zigzag shapes, we should pay more attention to the reasonable and useful application of tensile clamping pads.

4. Pay attention to the stress conditions of the small feet, fine teeth, long legs, cambered surfaces, inclined planes, openings, viewpoints, etc. of profiles with large width thickness ratio, extended wall length, large radian, great difference in wall thickness, and strange shapes, so as to avoid the defects of profiles or point-shaped scale deformation, distortion, helix, etc.

5. Due to the heat blocking effect of the top, the aluminum profile with high requirements for decorative appearance must be turned up and down, back and forth, so as to facilitate uniform heat dissipation and reduce the shortcomings of transverse bright spots caused by uneven heat dissipation and different crystallinity, especially the aluminum profile with large width and wall thickness.

6. In the process of picking, moving and stretching, it is forbidden to rub, pull, stack, block or wind each other, and a certain interval should be left between them. Aluminum alloy profiles that are prone to twists and turns and have long and short discharge lengths should be treated in time, and maintenance and treatment should be carried out when necessary.

The precautions for aluminum profile shell in the stretching process mainly include the above six points. Our aluminum profile shell has excellent corrosion resistance. And it is highly recyclable, in line with the ecological development concept of energy conservation and environmental protection.